Pneumatic cylinders are widely used in industrial automation to convert compressed air into mechanical motion. They are found in packaging lines, textile machinery, automotive plants, and various manufacturing processes. While pneumatic cylinders are known for their reliability, failures can still occur—often due to preventable reasons.

In this article, we’ll cover the most common causes of pneumatic cylinder failures and offer practical tips to avoid downtime, improve performance, and extend equipment life.

Understanding Pneumatic Cylinder Function

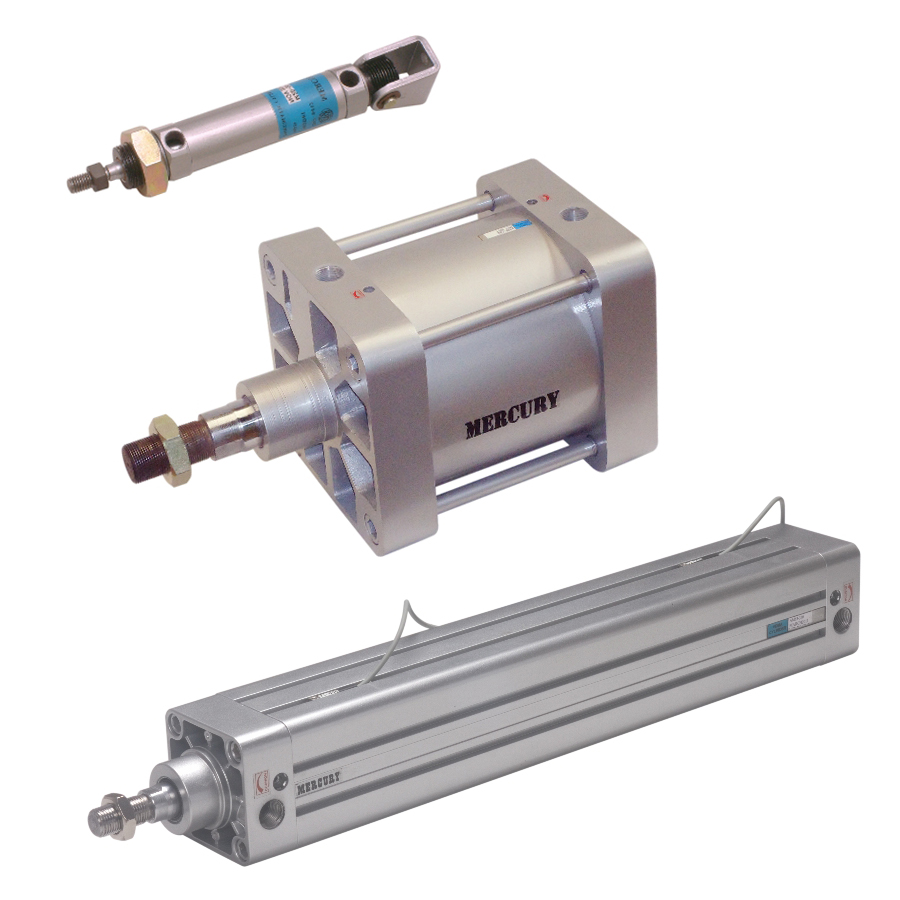

Pneumatic cylinders (also known as air cylinders or actuators) operate by using compressed air to generate linear or rotary motion. They are available in different types such as single-acting, double-acting, compact, and rod less cylinders—each designed for specific force and motion applications.

Explore the full range of pneumatic cylinders here.

Top Causes of Pneumatic Cylinder Failures:

Issue: Dust, oil, water, or rust particles in the compressed air can damage seals and internal surfaces.

Prevention: Install proper air filters and use auto drain valves to keep the air supply clean and dry.

Issue: Misaligned mounting can cause side loading, which leads to uneven wear, rod bending, or seal damage.

Prevention: Ensure precise alignment during installation and use mounting accessories like rod clevis , swivel rod eye,self aligning rod coupling or pivot brackets.

Issue: Lack of lubrication increases friction, accelerates wear, and may lead to cylinder sticking.

Prevention: Use lubricated air with the help of an Lubricator or our proprietary autolube system . Always check the manufacturer’s lubrication guidelines.

Issue: Operating a cylinder beyond its rated load or pressure limit can lead to mechanical failure or seal blowout.

Prevention: Choose the correct bore size and pressure rating based on the load requirements of your application.

Issue: Very high or low ambient temperatures can affect seal material and cylinder performance.

Prevention: Select cylinders with seals and materials rated for your working environment (e.g., Viton seals for high temp).

Issue: Skipping routine checks or ignoring early signs of wear can turn minor issues into major failures.

Prevention: Implement a preventive maintenance schedule to inspect, clean, and service cylinders regularly.

Tips to Extend Pneumatic Cylinder Life

Industries That Rely on Pneumatic Cylinders

Technical Highlights of Our Pneumatic Cylinders

Explore detailed specs and models on our Pneumatic Cylinders Product Page.

Conclusion

Pneumatic cylinder failures can disrupt production and increase maintenance costs. However, by understanding common failure points and taking preventive action, you can significantly enhance the efficiency and lifespan of your pneumatic systems.

Need help choosing the right pneumatic cylinder for your setup? Contact our team for expert guidance and reliable solutions tailored to your application.

WhatsApp us