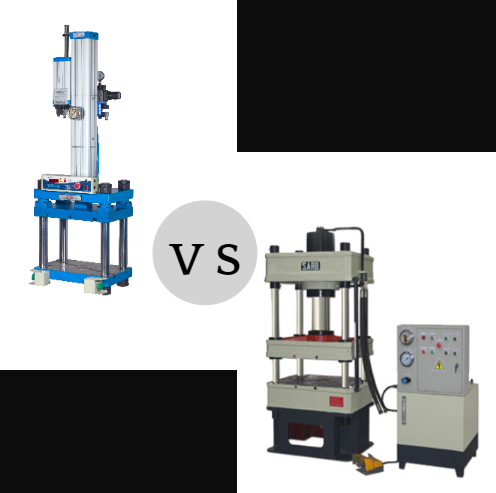

Many of our first-time users ask us the difference between hydro pneumatic and hydraulic presses. Understanding the differences between the two can help you make an informed decision that aligns with your specific requirements. Let’s delve into a comparative analysis to see which system comes out on top in various aspects:

Approach Speed:

Hydropneumatic Press: Boasts a fast approach stroke, ideal for applications where speed is of the essence.

Hydraulic Press: has a much slower approach stroke

Cycle Time:

Hydropneumatic Press: Known for lower cycle times, ensuring efficiency and productivity.

Hydraulic Press: Typically entails longer cycle times which reduces overall productivity

Power Pack:

Hydropneumatic Press: Does not require a power pack, simplifying setup and reducing initial costs.

Hydraulic Press: Requires a power pack for operation, adding to the initial investment.

Energy Consumption:

Hydropneumatic Press: Boasts lower energy consumption, contributing to cost savings per component which leads to better ROI

Hydraulic Press: Tends to consume more energy during the stroke as well as during idle times, which could impact operational costs significantly .

Initial Investment:

Hydropneumatic Press: Offers a lower initial investment, making it an attractive option for businesses.

Hydraulic Press: Involves a higher initial investment due to the need for a power pack and associated equipment.

Size:

Hydropneumatic Press: Features a smaller footprint, making it suitable for applications with limited space.

Hydraulic Press: Typically occupies a larger footprint, requiring more space in the facility.

Serviceability:

Hydropneumatic Press: Easier to service, minimizing downtime and maintenance costs.

Hydraulic Press: May take longer to service as well as costs more due to the more expensive components of hydraulic systems.

Oil Consumption:

Hydropneumatic Press: Requires less oil, reducing operational costs and environmental impact.

Hydraulic Press: Utilizes a larger quantity of oil, which can increase maintenance expenses and environmental concerns.

Energy Efficiency:

Hydropneumatic Press: Offers higher overall efficiency, particularly for lower tonnages (up to 45 tonnes).

Hydraulic Press: Shows lower overall efficiency, especially for lower tonnages, which could impact long-term operational costs.

Stroke Length:

Hydropneumatic Press: Typically features a limited power stroke, suitable for specific applications.

Hydraulic Press: Allows for longer power strokes, providing versatility in various tasks.

Below is the operating cost comparison between Hydropneumatic and Hydraulic presses

| Cylinder model | A041150 | |

| Number of strokes per min | nos | 10 |

| Unit cost of electricity | Rs/KWH | 13 |

| Work done/ minute | HP | 0.77 |

| Energy consumed per hour | KWH | 0.57 |

| Cost per component in Mercury Hydro Pneumatic Machine | Rs | 0.0124 |

| Motorcapacity for equivalent tonnage of Hydraulic machine | HP | 3 |

| energy consumption by Hydraulic machine | KWH | 2.24 |

| Cost per component on and equivalent Hydraulic machine | Rs | 0.048 |

| Saving by Using a Hydro Pneumatic machine | 74.44% |

Hydropneumatic presses excel in energy efficiency, initial investment, Speed and space-saving aspect over Hydraulic systems and hydraulic presses are only advantageous in applications wherrin a power stroke larger than 24mm is required.